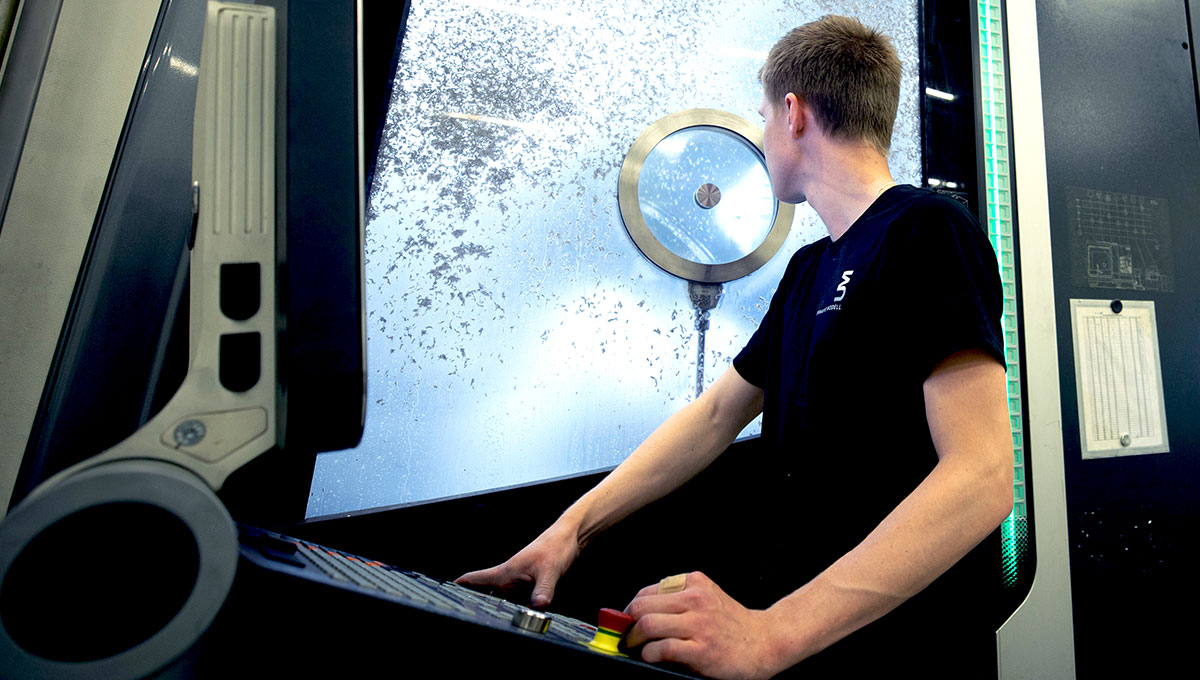

Ledande inom vår bransch

Unnaryd Modell är en utvecklingspartner med hög teknisk kompetens och korta beslutsvägar. Vi är en helhetsleverantör av prototyper och specialserie. Affärsfokus är mot fordonsindustrin och krävande applikationer inom andra områden.

Europas främsta prototyptillverkare

Vi är ett kunskapsföretag som brinner för att producera, hitta smarta tekniska lösningar och utveckla oss själva och våra processer. Vi delar med oss av vår kunskap och försöker underlätta våra kunders arbete. Med långsiktigt fokus arbetar vi för att vara våra kunders förstaval.

Starta din karriärresa med oss

På vår karriärsida kan du upptäcka allt som vår organisation har att erbjuda. Vi är en dynamisk arbetsplats som värdesätter våra medarbetare och som är engagerade i att skapa en miljö där alla kan trivas och utvecklas.